INTRODUCTION

Machine Down Time Monitoring

A Machine Downtime Reporting System is a tool or module within industrial monitoring and maintenance systems that tracks, records, analyzes, and reports periods when machinery is not operational—either due to breakdowns, maintenance, or other issues

🎯 Purpose:

To reduce production losses and improve operational efficiency by:

-

Identifying causes of downtime

-

Monitoring frequency and duration of downtime events

-

Supporting preventive maintenance planning

-

Improving machine utilization

🛠️ Key Features of a Machine Downtime Reporting System:

-

Automatic and Manual Logging:

-

Sensors/PLC detect when a machine stops

-

Operators can manually enter downtime reasons (e.g., maintenance, tool change, material shortage)

-

-

Downtime Categorization:

-

Scheduled vs. unscheduled

-

By cause: mechanical failure, electrical issue, operator error, etc.

-

-

Real-Time Alerts:

-

Notify maintenance teams or supervisors when machines stop unexpectedly

-

-

Reports and Dashboards:

-

Daily/weekly/monthly downtime reports

-

Top 10 machines by downtime

-

Pareto analysis of downtime causes

-

-

Integration with Other Systems:

-

Works with MES (Manufacturing Execution System), SCADA, ERP, or CMMS (Maintenance systems)

-

System Architecture

🎯 1. Data Acquisition Layer

-

Edge or PLC Devices / Sensors: Collect machine telemetry (e.g. status, run/stop signals).

-

Connectivity Middleware: For on-prem machines, solutions like AWS IoT Greengrass or MQTT brokers capture and securely forward data.

🛠️ 2. Ingestion & Real-time Processing

-

Streaming Pipeline: Use services such as Amazon Kinesis Data Streams/Firehose, or open-source counterparts (Kafka) to ingest live telemetry.

-

Filtering & Aggregation: Serverless functions (e.g. AWS Lambda) detect downtime events, calculate durations, and aggregate metrics.

🔍 3. Storage, Enrichment & Metadata

-

Real-time DB: Systems like DynamoDB store current machine status, tagging/grouping configurations for fast dashboard updates.

-

Historical Archive: Telemetry gets persisted to data stores like S3 for long-term insights. ◆

-

Catalog + BI Prep: AWS Glue catalogs S3 data, with query/reporting via Athena and visualization in Quick Sight.

📊 4. Visualization & Reporting

-

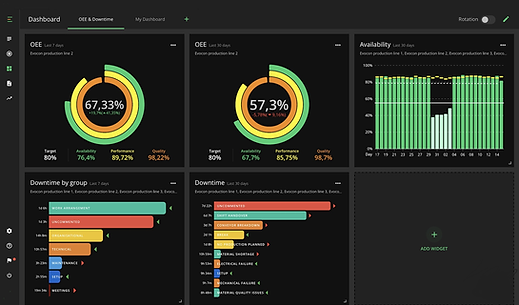

Real‑time Dashboard: Web app (hosted on S3 + CloudFront with AWS AppSync or equivalent). Displays heatmaps, status tiles, downtime trends. (shown in image 1).

-

Historical Reports: BI dashboards spotlight trends (e.g. pie charts of downtime reasons, time-series charts; see image 2).

-

Operator Input UI: Tablets or kiosks at machines prompt operators to classify stops (planned vs unplanned, reason, operator).

⚠️ 5. Alerts & Decision Support

-

Anomaly / Predictive ML: ML models or rule-based systems flag abnormal downtime or forecast failures.

-

Event Correlation: Tools like Prometheus/Alert manager/Grafana can correlate downtime with other system metrics.

-

Notifications: Alerts are routed via email, SMS, or Slack when thresholds (SLA breaches, repeated faults) occur.

👉 6. Integration & Feedback

-

Plant Integration: Tie outputs into MES/ERP systems to feed maintenance schedules, production planning.

-

Continuous Improvement: Historical root-cause analysis and KPI monitoring enable process refinement

Overview Dashboard

*Utilization Rate:

Utilization Rate%: We are calculating the utilization of machine in percentage. Formula = (Operational Run Time/Total Run Time)/100

*Average Cycle Rate

Avg Cycle Time: It is the Average Cycle Time of the Molding Machine Cycle. Formula: Operational Time / Cycle Counts

*Operational Time

Operational Time: If the machine feeding is not done within 2 minutes and machine hydraulic motor is on then the system stops the counting of operational time

*Total Time

Total Time: Total runtime of machine is calculated by the run status of the hydraulic motor.

*Cycle Count

Cycle Counts: Counting of the cycles is being done by the status of the machine door close feedback.

*Machine Status

Machine Status: Realtime Machine Status (If hydraulic Motor is on then it shows ON)

*Line Chart

Line Chart: Red line shows the Machine run time per hour and green line shows the operational time per hour

*Colum Chart

Cycle Counts Per Hour

*Navigation Menu

*Real Time Closed And Heating Status

*Real Time Machine Status

Reports

1. Navigation Menu

2. Select Timespan For Report

3. Select Interval

4. Click Download Report To Get Report

Daily Report

A daily machine downtime report is a structured summary—typically prepared at the end of each shift or day—designed to capture downtime events accurately, analyze issues, and drive continuous improvement. Here's how to build one effectively:

1. Objectives of a Daily Report

-

Log every downtime event (planned and unplanned).

-

Record key details: when, which machine, for how long, and why.

-

Assign responsibility and capture verification.

-

Provide immediate insights and prompt corrective actions.

📋 2. Essential Sections & Fields

A typical Daily Downtime Report Form includes:

-

Report Metadata: Date, Shift, Prepared by, Location.

-

Event Entries (for each downtime):

-

Machine ID

-

Downtime Start & End

-

Duration (auto-calculated or manually entered)

-

Category (e.g., mechanical issue, setup change, material shortage, other)

-

Description/Reason (free-text, dropdown, or checklist)

-

Planned vs. Unplanned (important for OEE and reliability analysis)

-

-

Verification: Verified by (person), signature or approval stamp.

-

Operator/Maintenance Notes: Optional comments or steps taken.

Hourly performance report

Downtime Reporting Supervisory Dashboard

A Downtime Reporting Supervisory Dashboard is a visual platform designed for supervisors and plant managers to monitor, analyze, and respond to equipment downtime in real-time and over historical periods. Here's a comprehensive breakdown:

Purpose & Benefits

-

Real-time detection: Shows which machines are running, idle, or in downtime right now.

-

Root cause insight: Displays Pareto charts and breakdowns by reason to highlight the key issues quickly

-

Performance comparison: Provides side‑by‑side views of shifts, machines, or lines to benchmark performance and identify weak spots

Downtime Reporting Display Module

A Downtime Reporting Display Module is a dedicated interface designed to clearly and visually present machine downtime data—making it easy for supervisors, operators, and managers to monitor, understand, and act on equipment stoppages.

🧩 What It Does

-

Show key downtime KPIs—including OEE, availability, MTBF, MTTR, and downtime duration—typically via gauges or summary tiles

-

Visualize downtime by reason—through Pareto charts or pie/bar graphs, showing which causes (e.g., breakdowns, material shortages, changeovers) dominate.

-

Offer timeline views—like Total Production Timeline™, shift-level charts or interactive Gantt-style visuals to spot patterns and correlations with shifts or events.

-

List detailed events—tables listing each downtime incident with start time, duration, machine, category, and notes

🛠️ How It Integrates

-

Automated data capture from PLCs, OPC UA, MT Connect, and shop-floor systems

-

Manual operator input supplements reason coding and root-cause details when required

-

Alerts and thresholds notify teams in real time when downtime exceeds configured limits or shifts